[China Packaging Network] Contract packaging suppliers or contract packaging companies must make a crucial decision during the contract's validity period: whether to continuously and repeatedly purchase packaging materials. These include labels, plastic films, composite paper, sealing devices, corrugated boxes, and other packaging containers. The clients—often brand owners or product manufacturers—have several standard arrangements they can entrust to their contract packaging companies:

1. The customer purchases the packaging materials and sends them along with the product to the supplier, who then handles the packaging.

2. The contract packaging company buys the materials based on the customer’s instructions on what to buy and where to source them.

3. The customer provides specifications for the packaging materials, and the contract packaging company is responsible for sourcing and purchasing them.

Which method suits your company best? In service-oriented business, the answer is often "it depends." To secure outsourcing contracts, contract packaging companies and material suppliers must strictly adhere to material specifications and maintain clear communication throughout the process.

For example, one company operates as both a contract packaging provider and a packaging material supplier, using all three methods simultaneously. In addition to offering full outsourcing services like hot press molding, it has also become the exclusive supplier for a packaging technology firm.

"A lot of our work needs to be done in advance," said Wolff, the company's CEO. "During the project design and planning phase, we stay closely connected with our customers. Our service projects have evolved from simply providing packaging solutions to implementing precise material orders and job guidance that are aligned with production schedules to prevent delays."

This requires thorough planning and estimates at the beginning of each project. "If you consider multiple design options, customers need to understand how these choices affect the final cost of the outsourcing service," he added.

From the perspective of material suppliers, it doesn’t matter who specifies or receives the materials, as ultimately, everything is done for the brand owners.

"We use all three approaches," said another vice president of sales at a contract packaging company. "When we provide packaging outsourcing services, we directly communicate with the contract packaging companies to determine what part of the contract will be outsourced. These details are discussed in advance, so we know exactly what packaging materials will be used. The closer we are to the real situation—such as the packaging structure, point-of-purchase display, or the products to be packaged—the better the services we can offer."

The company offers packaging boxes and pallet protection programs, producing items like paper corner protectors and often including printing services. "These are essentially cost items," said Fast. "Optimization is very important. For instance, the size of corrugated paper used for edge protectors. When optimizing for cost, regardless of whether the supplier works with an outsourced service provider or a branded vendor, it's essential to test the products under the framework of the International Safe Transit Association (ISTA) standards and keep the latest technical parameters until all requirements are met."

Brands, contract packaging companies, and packaging material suppliers face the challenge of bridging communication gaps. Therefore, as a cost-saving measure, it's acceptable for any party to avoid fraudulent practices. For example, brand owners may already have an established outsourcing partner, but other contract packaging companies might still be invited to bid. In such cases, it's vital to confirm that all participants fully understand the bidding requirements, as new providers may lack sufficient packaging or material information. Although they may submit a low price, it might not meet the brand’s expectations. Confirming this is critical.

Article Source: China Packaging Network | For reprint articles, please indicate the source or keep the original source path

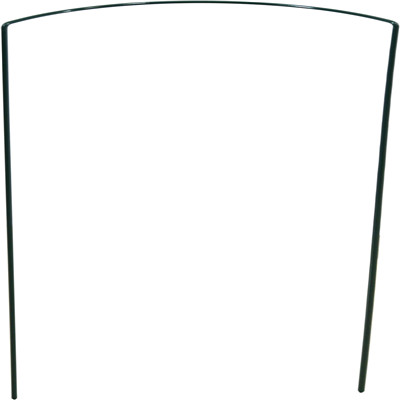

Garden support is the ideal support for any climbing plants, vine plants, flowers and leaves. The plant finds support by growing up through the stake, to keep the plant up. We have several kinds of support, twisted spiral tomato support, plant support, garden trellis.

Ÿ Materials: Carbon steel wire.

Ÿ Surface Treatment: Galvanized, Plastic coated

Ÿ Clour: Green, Black,etc.

Benefits

Ÿ High strength, acid-resisting, alkali-resisting

Ÿ Heat-resisting and wear-resisting

Plant Support, Galvanized Twisted Spiral Tomato Support, Painted Galvanized Multi-Stake, Garden Support

DINGZHOU TIAN YILONG METAL PRODUCTS CO., LTD. , https://www.wiremeshsolution.com